Hawkscan Vehicle Classification

& Management System

LIDAR SCANS 75 TIMES EVERY SECOND

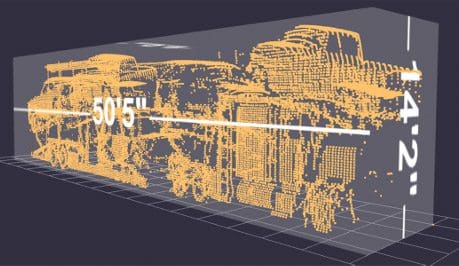

The HawkScan solution measures and classifies vehicles during normal traffic flow. Eye-safe LiDAR sensors scan objects 75 times a second, enabling fully-automated length, width, and height measurement with the vehicle speed and movement direction. The measurement data recorded to generate a 3D model for each vehicle, visualizing excessive heights, widths, and lengths. Also, the solution enables the counting of axles, axle spacing, and vehicle type.

HOW IT WORKS

Vehicle enters the lane at highway speed.

Sensors measure the vehicle’s height, length and width.

Cameras photograph the vehicle and scan its license plate.

State

H P T 1 2 3

Software produces a 3D model of the vehicle.

The vehicle’s axle count and spacings are calculated and displayed.

The vehicle’s type is determined by the software. The measured results are checked against the issued permit for accuracy and compliance.

HAWKSCAN BENEFITS

EFFICIENCY

Automated vehicle attribution, verification and integration with jurisdiction technology allows OS/OW law enforcement professionals to prioritize and focus efforts on critical and immediate roadway safety issues.

RETURN ON INVESTMENT

Each bridge hit costs US jurisdictions an average of 400K in damage and repair, in addition to the direct impact to the motoring public, including traffic congestion, detours, and personal safety.

SAFETY

Automated vehicle attribution improves precision and reduces human error thereby increasing roadway safety, infrastructure integrity and preservation of law enforcement resources.

HyPoint provides onsite installation of sensors, mounts, and power. The HawkScan software aligns and calibrates the sensors for accuracy and repeatable data.

HAWKSCAN FEATURES

SENSORS

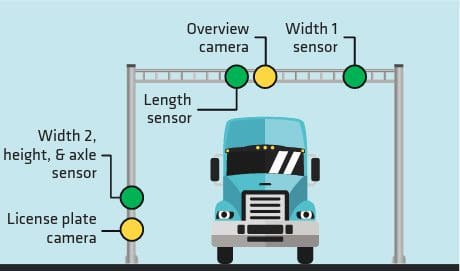

Sensors mounted on a pole standard capture vehicles in a single lane of travel at controlled speeds. Trucks are scanned in real-time by the sensors, which consist of three LiDAR (laser) scanners and one high-resolution camera.

SOFTWARE

A web-based dashboard display transactions in real-time, compiling all crossings in a list format by occurrence. The displayed data includes the vehicle’s classification, height, length, width, a single overview image, the vehicle license plate, the axle count and dimensioning, and a timestamp.

CAMERAS AND SENSORS

- Automated License Plate

- Reader LiDAR Profiling System

OPERATING CONDITIONS

HawkScan is designed to work in an outdoor environment and features sensor heaters and fog correction. The operating temperatures are -40 degrees (F) to 140 degrees (F). The eye-safe, infrared sensors have a scanning frequency of 100Hz, providing a high-resolution point cloud for each vehicle.

DASHBOARD

The provided ESRI ArcGIS web-based dashboard displays transactions in real-time, compiling all crossings in a list formatted by order of occurrence. Data displayed include the vehicle’s classification, height, length, width, a single overview image, the vehicle license plate, the axle count and dimensioning, and a timestamp. As transactions occur, the information is recorded in a local database on the computer and the web interface allows users in the weigh station to scroll back in time to view recent vehicles. A 3D point cloud is included to verify vehicle dimension verification and allows users to see the vehicle dimensions. Users can filter any of the data points to perform custom searches to verify vehicle dimensions and permitting compliance.

AXLE DETECTION

The system detects vehicle axles. This information is recorded in the HawkScan software and displayed on the dashboard, allowing the system to identify the type of vehicle and provide axle spacing calculations for each vehicle.

HawkScan Sensor configuration

Software showing license plate scan

Software showing 3D point, axle count and spacing

HAWKSCAN BENEFITS

Watch HawkScan in action. As an oversize truck enters a weigh station, it is scanned and modeled by HawkScan. The truck is measured on all three axes (length, width, and height) using the HawkScan sensors, and the truck is weighed. All of this is done in real-time, allowing for efficient movement of vehicles through the system. All scans appear in an intuitive dashboard, and data is saved in a cloud platform for potential later retrieval and use.